Finding the ideal drag

The pressure was on for the aerodynamics team from ETH Zurich. In constructing the Citius bobsled, gaining tenths of a second by making the shape as aerodynamic as possible was of the essence. Beating the bobsled builders at their own game was no easy task.

Streamlined shapes of cars or bobsleds generally appear as an aesthetic accompaniment. Consequently, Patrick Jenny, a professor at the Institute of Fluid Dynamics at ETH Zurich, is convinced that a sketch by an artist depicting a streamlined bobsled could have good aerodynamic qualities. Unfortunately, such drafts rarely coincide with the actual needs of a bobsled or the strict regulations that should be observed when building one.

Qualitative approach

The responsibility of Patrick Jenny’s team and his PhD student Benjamin Zoller was to optimize the bobsled’s aerodynamics without contravening the strict rules of the International Bobsleigh Association. They began by analyzing a report that a Master’s thesis on a two-man bobsled was based upon in Holland. Zoller then conducted qualitative tests using a model bobsled in a water channel. A 3D printer had produced the model using the digitalized data from the four-man bobsled used by the Swiss team last season. The scientists used plasticine to alter the shell of the model several times, each of which they tested in the water channel to find out which design was the most aerodynamic.

“The water channel tests are just the ticket for qualitative assessments”, explains Jenny. After all, compared to the speed of sound the gas – or air in the case of the bobsled – reacts slowly in currents, like water. The flow patterns quickly reveal just how good the aerodynamic behavior of the test vehicle is.

Water channel and ice track for streamline analysis

In the winter of 2007/2008, test runs were conducted with an original two-man bobsled at the St. Moritz ice track, which the team had covered in woolen threads. Both the tests at the ice track and in the water channel were able to shed some light into the streamline behavior and the flow patterns. As they moved in the wind, the threads provided the researchers with more detailed knowledge, such as the aerodynamic behavior of deflectors that are fixed to the side of the bobsled and which are difficult to see in the water channel model on account of their small size. The deflectors prevent the blades from snagging on the ice track when there is lateral contact and are therefore mandatory. However, they also have an adverse effect on the aerodynamics.

Athletes have final word

The researchers fed the data regarding the bobsled’s streamline properties into particular simulation programs to find the ideal shape. “When it went smoothly, it took twenty-four hours to simulate a shape”, says Zoller. There is not much room for improvement, however: if the bobsled were situated in a vacuum, meaning that the aerodynamic resistance would be next to zero, it would only be possible to save a maximum of 4 to 5 seconds, explain the scientists. Aerodynamics therefore only really comes into play when hundredths of a second decide the winner. Despite the technology, it is still the athletes who make the difference, stresses Jenny.

At the bobsled’s nose and the pilot’s helm, the so-called stagnation points, the current is slowed down to zero. The pressure loss caused by this accounts for up to ninety percent of the aerodynamic resistance, explains Zoller. Consequently, the nose needs to be constructed in such a way that the streamlines are deflected along the side of the bobsled. The next crunchpoint comes where the streamlines come off the bobsled – at the back where the athletes climb on board. The bigger the access point is, the greater the aerodynamic resistance. “If the current were completely in contact with the back, such as a ball it could flow around slowly, there would be a second stagnation point with the same pressure as at the front and the pressure loss would therefore be zero”, says Zoller. As this is not possible in a bobsled, however, the nose and the rear have to be optimized to minimize the pressure loss that makes up the aerodynamic resistance.

Besides the shell, the aerodynamics team paid particular attention to the nose, deflectors and the start straps in their attempts to improve everything in terms of aerodynamics. However, their options – especially in the simulations – were limited for reasons of time and money, the scientists explain. The lack of scope was also a challenge. Consequently, the team worked closely with the former bobsled pilot and present bobsled builder Christian Reich, who builds successful bobsleds without the know-how that is used at ETH Zurich.

Interface in the project

The Kinematik II team headed by Paolo Ermanni from the Institute of Mechanical Systems ultimately constructed the shell of the bobsled in conjunction with the industrial partners on the basis of the aerodynamics team’s data. The Kinematik II team, especially Thomas Kern, was responsible for the project management, which is where all of the sub-projects converge. Kern went into industry in the spring and was succeeded by Carlo Zimmermann.

Once the aerodynamics team had defined the ideal shape, the Kinematik II team was able to begin the construction of the shell. “The important thing was to find the ideal rigidity and strength for the bobsled with the right material”, says Zimmermann. The construction is supposed to comply with the regulations and give the bobsled the right weight. The team decided on carbon fibers for the material and started with the construction last year in May in collaboration with the company Ruag. After the first two prototypes had been tested, the bobsled builders received their final feedback. It became apparent that the deflectors were constructed too weakly and the shell caused too much juddering for the crew. The team made some improvements and reinforced the shell inside the bobsled to retain the aerodynamic shape of the exterior. All the teams continued to tweak the design right up until the bobsled went into serial production in mid-April.

Last but not least: helmet aerodynamics

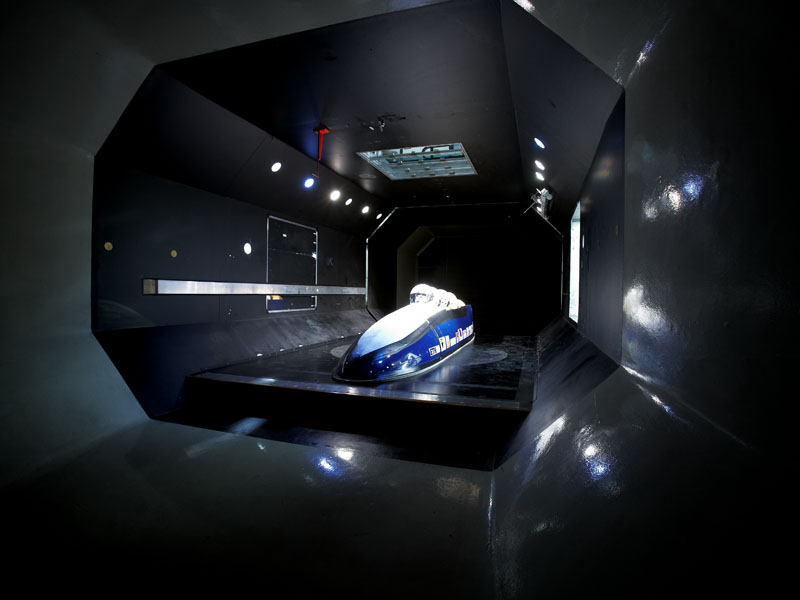

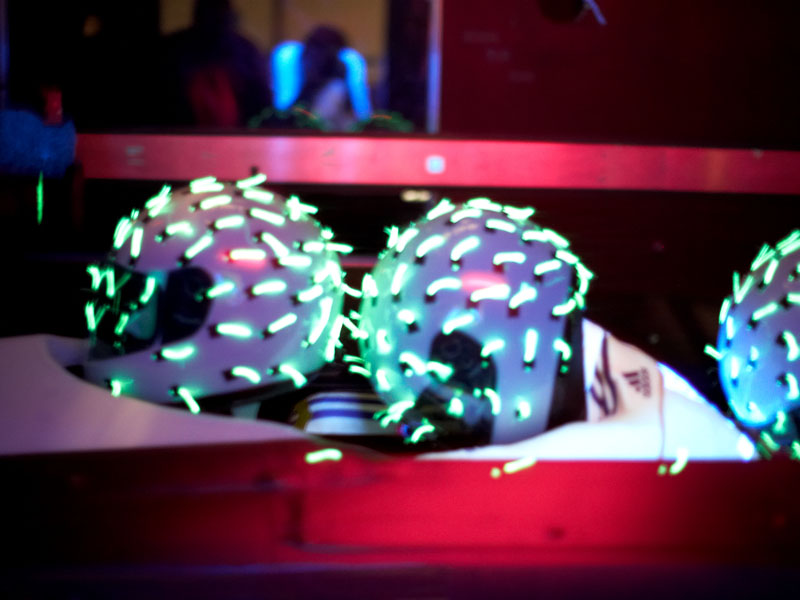

The team can now devote its full attention to another important aspect: the aerodynamics of the helmets. Severin Merk addresses this in his Master’s thesis: he is testing different motorbike helmets from the company IXS in ETH Zurich’s wind tunnel. Dolls used to simulate the athletes wear the helmets in the bobsled, which is exposed to wind strengths of up to 180 kilometers per hour in the wind tunnel to measure the aerodynamic resistance of the helmets. Woolen threads were also used here to study the flow behavior. The ideal helmet configuration was found by using scales to measure the aerodynamic resistance. The helmets are still too heavy for the crew, however – they prefer light ones that are not too big so that at least the pilot can move his head easily and have the best possible field of vision.

Even if they are keeping the details secret, the teams have given the Citius bobsled the thumbs up.

READER COMMENTS